Over the course of the last century, aircraft development has seen strides that could not have been predicted early on. Aviation technology and aircraft maintenance software have exponentially grown over the past decades. The growth has allowed airplanes of different sizes and shapes to operate seamlessly.

However, if one looks to some of the main components of a plane, their purpose has remained static. Take, for instance, the engine of an aircraft. Engines have certainly come a long way since the early twentieth-century. The way they function, on the other hand, can differ quite widely. With different planes in existence today, also comes different engines that power them.

Here are six different types of engines used in aircraft:

1. Turbojet Engines

As one of the first variations of aircraft engines invented, turbojet engines function based on a set of core principles. Through a combination of air intake, compression, and power, coupled with an exhaust nozzle, the engine is able to work. To begin the process, turbojet engines take in air and efficiently directs it to the nearby compression blades.

The compressor, which acts as a series of fans, compresses the air enough so that it can align with the combustor chamber. As soon as this mixture of air and fuel passes through the turbine, it exits the engine via the exhaust nozzle. This, essentially, allows the plane to push forward.

2. Turboprop Engines

Another type of engine used in aircraft is the turboprop. Whereas turbojet engines are not known for being fuel-friendly, turboprop engines are the opposite. This engine is a variant of its predecessor, and is connected to a propeller via a respective gearing system. First, it spins a shaft, which is connected to the gearbox system.

Once this is fired up, the gearbox slows down the rate of spinning. At this point, this allows the slowest moving gear to connect to the aforementioned propeller. The propeller then begins rotating through the air, inevitably producing enough thrust to get the aircraft moving off the ground.

3. Turbofan Engines

Like the turboprop engine before it, a turbofan is an offshoot of the original turbojet. The best part about it is that it combines the best of both those engines, in order to produce a more streamlined engine. In essence, turbofans work by attaching a fan in front of the actual engine.

This fan helps to stimulate additional thrust, while also cooling down the engine and mitigating the amount of audible noise. Air is divvied up into two streams, with one stream flowing through the engine. The other penetrates the engine’s core. Since there is an additional fan in front of the engine, turbofans turn out to be larger and heavier than its counterparts.

4. Turboshaft Engines

Most turboshaft engines aren’t necessarily built on the typical airplanes you would see at an airport. That is because these engines are primarily attached on helicopters, and aircraft of similar structure. Turboshafts work by leveraging the power produced to turn a turbine. This is in contrast to other engines, where thrust is usually formed through the back.

Most turboshaft engines aren’t necessarily built on the typical airplanes you would see at an airport. That is because these engines are primarily attached on helicopters, and aircraft of similar structure. Turboshafts work by leveraging the power produced to turn a turbine. This is in contrast to other engines, where thrust is usually formed through the back.

In comparison to turbojets, turboshaft engines operate very similarly. In regards to the turbine, the attached power shaft controls the transmission. This allows power to then make its way to the rotor blade, resulting in the helicopter being able to move. Although the gearbox systems can be structured in a complicated way, turboshaft engines are still powerful in their own right.

5. Ramjet Engines

All of the preceding engines can be compared to one another in some fashion. With respect to ramjet engines, weight is abundantly less than its counterparts. Regarded as one of the lightest variants of aircraft engines available, ramjets work in a very unique manner.

For starters, the rotating mechanisms, found in other engines, are not present in this type of engine. Thrust is also not developed as it normally would be in a turbojet engine, for example. Instead, the ability to move forward is created just below the speed of its sound. Ramjet engines, as a result, require some form of assistance to fully get going.

6. Piston Engines

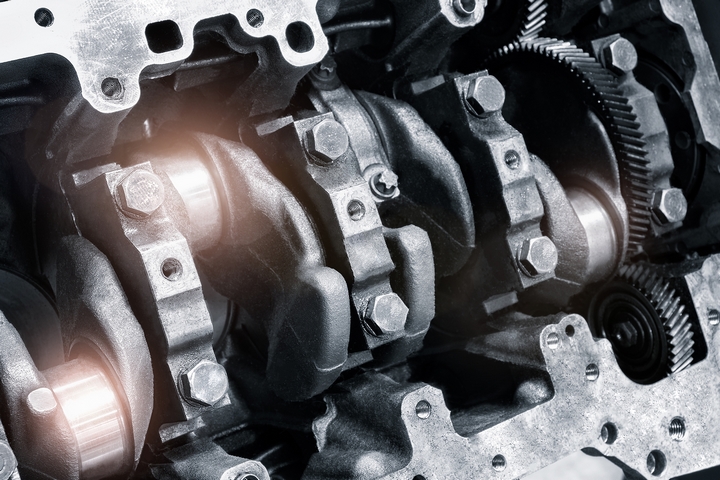

Commonly referred to as a reciprocating engine, pistons work through the use of one or multiple pistons. By implementing the use of an internal combustion engine, these pistons are then able to transfigure the resulting pressure into rotational motion. Think of the engines you would normally find in ground vehicles, such as a car.

By extending the shaft of the engine in a car, and connecting a propeller to it, the desired rotation can be created. For most modern-day aircraft, however, this type of engine is usually reserved for only private, single airplanes.

Although there are multiple variants of aircraft engines in existence, a standard set of core principles allow them to create motion. Some looker cooler than others, but they all work to achieve the same purpose; getting the plane off the ground!