In a world where every business is competing for the audience’s attention, print marketing is an effective tool due to its ability to make a good first impression. With well-designed brochures, business cards, posters, flyers and other promotional materials, you can captivate your audience and carve out a niche for yourself. However insignificant it may seem, the type of print finishes applied can either make or break a design.

Business entities must come up with strategies to help them fully exploit the different types of print finishes available. Here are the different types of print finishes you can try out to make your print materials stand out from the crowd:

1. Varnishes

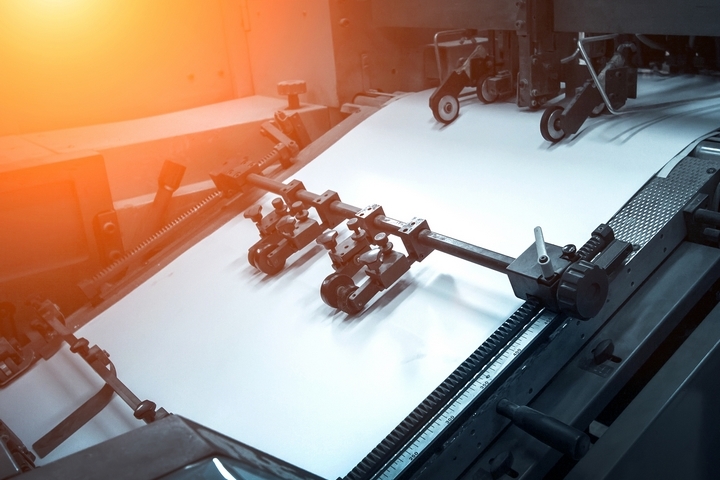

Often linked to wood, a varnish refers to a liquid coat added onto the surface of the paper stock to create a smooth and regular finish without adding too much extra weight. Besides enhancing the preservation of printed materials through sealing, print varnishes also provide a protective layer over the paper stock.

These types of print finishes is preferred for materials such as brochures, magazine pages and covers. For best results, apply varnish right after the printing process before you begin cutting and binding the sheets to increase the production and drying time. The most common types of varnish include gloss varnishing, which makes printed photographs or pictures look more appealing on brochures.

Other types include the more non-glossy matte varnishing, the moderately subtle and glossy silk varnishing, and machine sealing. The UV varnishing uses the ultraviolet technique to produce a transparent finish for your print materials.

2. Lamination

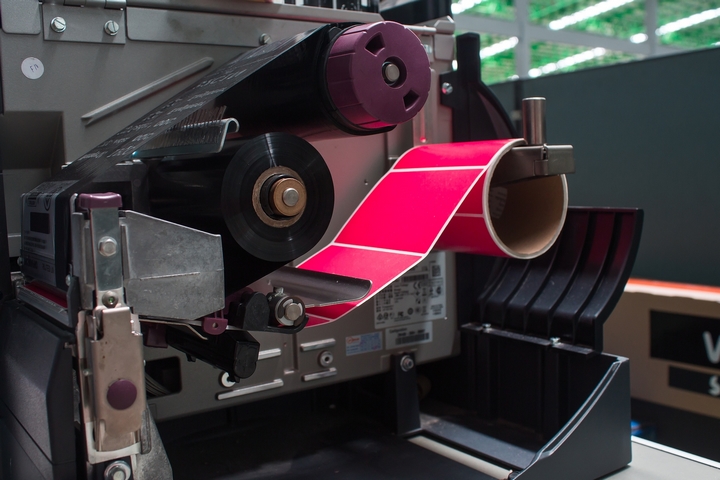

If you are searching for a solid print finish with a modern look, one that blends with lively colours, offers toughness and gives off a classic yet elegant vibe, lamination is one of the best methods for print finishing. Be it a gloss, matte or satin finish, lamination adds a thin layer of protective plastic.

This type of print finish is easily identified by touch due to the smooth water and tear-resistant finish. Gloss laminates tend to contrast photos and images better and are sharper. Matte laminates are more toned down and somewhat similar to varnishes. However, the print finishing you use depends on your needs and the expected outcome.

3. Foil Stamping

In essence, foiling is a print finishing technique where the metallic foil or any other malleable metallic material is applied to the paper stock using a heated metal die and a foiling stamping machine. The heat-processed coat is added onto parts of the design, text or logo, to create contrast and emphasis. When alongside other print finishing techniques, such as embossing, foil stamping works even better.

Remember, success is not just about crafting the perfect message, offer or design. You can equally increase your response rate and sales if you make use of this technique. Gold, silver, pigmented, holographic, and security are some of the foil varieties you may encounter.

4. Embossing

Simply put, embossing refers to the raising of particular parts of a page to lay emphasis and improve the texture. Physical depth is added to the original elements, thus creating shadows and highlights in the print material’s design.

This type of print finishing is also distinct in the sense that the messages and images can plainly be felt by the target audience. Sometimes, embossing is used in conjunction with other finishing techniques to improve its effectiveness.

5. Debossing/Letterpress

This is undoubtedly one of the most ancient printing techniques as it dates back to 1439. In contrast to embossing, which raises the page elements, debossing involves a block template of raised letters that are inked up and pressed onto the paper’s surface, recreating the letters in reverse.

These types of print finishes ideal for adding physical depth to your designs, decorative and vintage effects and setting your business apart.

6. Die-cutting

This entails cutting shapes or designs out of paper stock using a steel-edged die. It could be rounded corners or patterns on the page surface. The technique is commonly used on stationery such as folders and business cards. Die cuts help you uniquely grab the audience’s attention with an unconventional print finish for your materials, while at the same time making a statement about your brand identity.

A simple rounded corner on a business card points to elegance and superiority, while a fun die-cut informs your customers about who you are and what you do. Your brand image is critical to business longevity, and die-cut print finishes can help you achieve the image you want, fast.

7. Metallic Inks

For a reflective appearance and bright finish, use metallic inks. These types of print finishes contain highly reflective and striking metallic components that make them perfect for adding that distinctive touch to promotional print materials. If you want the lettering or logo to ‘pop’ while still maintaining a subtle finish, this should be your go-to print finishing technique.

In as much as these print finishing techniques may come with additional production costs, the return on investment is much higher.