At some point, 3D printing was just a tool for hobbyists. Today, it has evolved into a technology that’s used by nearly every industry. Now, it’s is being used in new and exciting ways in the construction industry. This technology is being implemented at an intense pace because of the many benefits it comes with.

3D printing is used in plenty of construction projects. The following are six ways 3D printing is used in construction projects worldwide:

1. Making Scale Physical Models of Construction Projects

Visualizing a 3D object such as a building or a home based on a 2D image or computer simulation is hard. Having an actual 3D architectural model helps in telling the entire story better, which is helpful when communicating and collaborating with a builder, an investor, a homeowner, or the planning commission.

With a scale model, concerns can be addressed before construction begins, saving you both time and money. A physical model gives a visual perspective that can’t be achieved with a regular drawing or blueprints. The models can either be monochrome or in full colour.

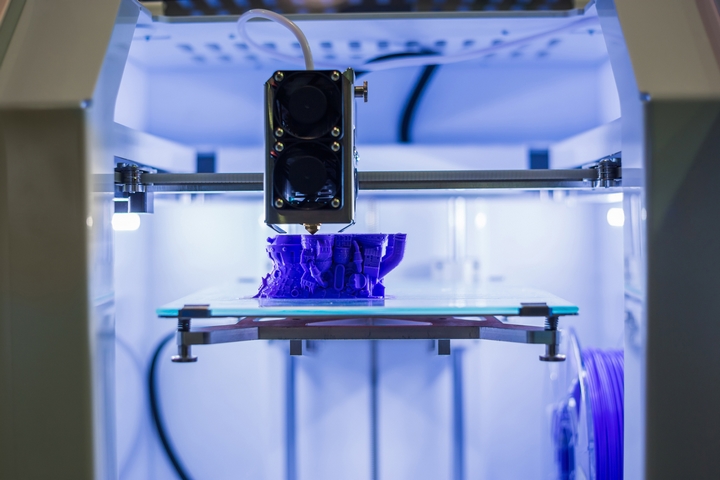

2. 3D-Printed Houses

For a long time, the construction industry has remained unchanged. Most structures still require workers to add layers of bricks atop each other manually. Today, this conventional approach is becoming outdated. Since it heavily relies on an individual’s labour and manpower, it results in a lot of waste, causes noise pollution, and has low productivity.

3D-printed houses are the light at the end of the tunnel for the construction industry. 3D printing a home is cheaper and more accurate. The completion time is significantly shorter, too. The trend of using this printing method in the construction industry is already starting to gain momentum, even though it’s entirely new.

For example, in France, you can find the first 3D-printed house with tenants living in it. It’s a four-bedroom property, which is a prototype for a larger project. It’s located in an area known as Nantes, and it took 54 hours to print.

Generally, local building codes don’t have a provision for 3D printed homes, which means the technology might not be applicable in some areas.

3. Building Pedestrian Bridges

3D printing can be used to construct pedestrian bridges that can handle as much weight as regularly constructed bridges. Such bridges offer architectural dynamism, are significantly cheaper to build, and take a short time to complete.

The longest pedestrian bridge to be constructed using 3D printing is located in Shanghai. It was designed by Professor Xu Weiugo. The bridge is made of a concrete mixture and is 26.3 metres long.

The inspiration for its design came from the ancient Anji Bridge, located in Zhaoxian, China. This single-arch structure features handrails that are partly shaped like flowing ribbons. To match the structural ability of conventional materials, a composite material containing polyethylene fibre concrete was used.

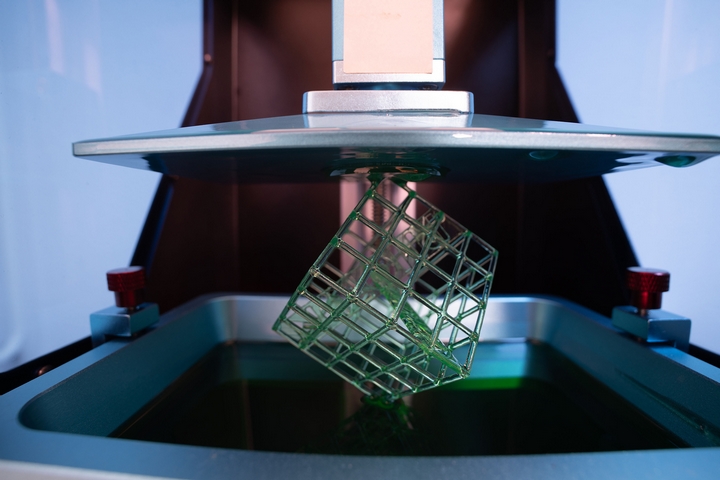

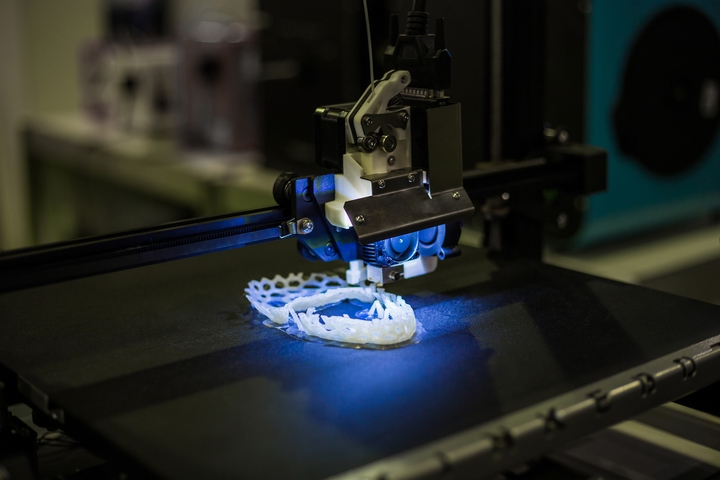

4. 3D Printing Construction Components

Today, people are getting more creative with construction components. Buildings, or structures in general, are taking all sorts of shapes and designs. In some cases, the construction components needed might be specific to a project, making them hard to find.

In such a case, 3D manufacturing comes in handy. From this perspective, 3D printing is used in construction to provide creative freedom and design flexibility. There are many different materials that can be used in 3D construction, so you can ensure creative, unique, and robust structures.

5. 3D Printing on Roads

Roads are a significant part of the construction industry. They are an essential part of any infrastructure. Generally, roads are expensive to build. Also, in most cases, the completion of a road is a time-sensitive issue. Using 3D printing for the construction of roads can cut down costs significantly. It can also allow engineers and developers to finish projects faster.

3D manufacturing reduces the need for manual labour by almost a half. It expands the room for creativity in design. A 3D bitumen printer is used to construct roads. Other than building a road, it can also be used for preventative maintenance, which is basically treating a crack in a road as soon as it’s identified. This extends the life of a road’s surface. Such printers can be attached to drones to eliminate the need for human labour, making things even more affordable.

Chipped strips, cracks, and potholes can cause severe damage to vehicles or even life-threatening accidents that risk the lives of drivers and pedestrians if left unattended. 3D preventative maintenance can help.

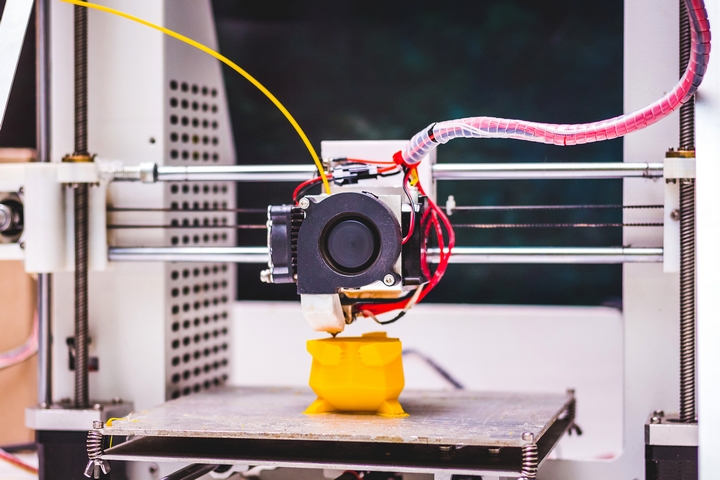

6. Beautifying Landscapes

When designing a landscape, 3D manufacturing can be used to give the space character and increase its visual appeal. You can achieve this by using accent features such as sculptures and vases.

The good thing is that 3D printing can be used to create or recreate almost anything. So, if a client wants a full-size sculpture of their favourite movie character or even a sculpture of themselves in their landscape, the only limitation is their budget. With the creative freedom that 3D printing offers, the possibilities as to how one can beautify a landscape are endless.

As 3D printing continues to gain popularity in the construction industry, expect to see more advancements in the field. People are now more open-minded than ever.